Facilities update: Sand Hill progress, trailer reuse, HVAC and work-order metrics

Get AI-powered insights, summaries, and transcripts

Subscribe

Summary

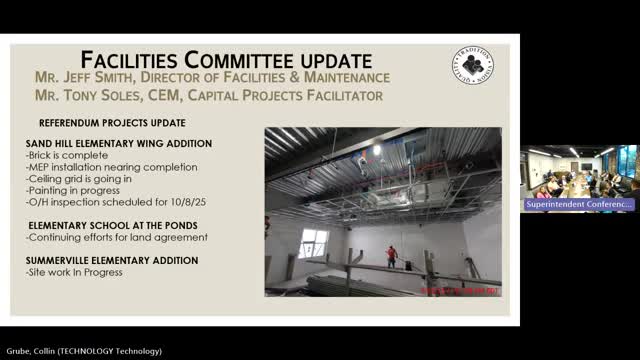

District facilities staff reported progress and delays across multiple capital projects — Sand Hill reconstruction, trailer relocation from Gregg Middle, Ashley Ridge sprinkler repairs, DOT-driven car-rider redesign — and gave maintenance metrics (about 1,200 September work orders; 88% completed).

Dorchester School District Two facilities staff gave the committee an update on ongoing construction, maintenance and operations during the Oct. 6 meeting.

Jeff Shope and other facilities staff said Sand Hill construction is near brick completion, but an overhead inspection was postponed because some smoke dampers had not arrived; staff expect the contractor to install dampers and reschedule inspection. Staff also said the district plans to reuse several trailers currently at Gregg Middle School at Sand Hill to save funds rather than buy new modular classrooms.

At the Ashley Ridge project, staff said they are awaiting approvals from LLR for revised sprinkler drawings and will replace several hundred feet of sprinkler piping after drawings are approved. Facilities staff explained DOT required a car-rider loop redesign at another site that adds roughly 4,000 feet of stacking to win DOT approval; that work is an ancillary project during construction.

Shope presented operations metrics: facilities logged about 1,200 work orders in September, with 88% completed during the month and an average turnaround of roughly 3½ days (outstanding work orders raised the overall average to about 5½ days). Staff said they plan to shift toward more preventive maintenance scheduling rather than a reactionary model.

Other updates included HVAC replacements with several purchase orders issued (rooftop units expected to be noninvasive), security vestibule installations at multiple schools (Austin Bailey, Fort Rochester, and a proposed vestibule at RISE), playground replacements funded from capital set-asides and locker-room/restroom renovation designs underway at several middle schools. Bus-maintenance civil drawings and a pre-engineered metal building procurement were described as moving toward construction.

Committee members and staff also raised school food-service issues: a committee member said Windsor Hill is having trouble keeping hot food warm and asked whether Aeramax (the district food-service contractor referenced in the meeting) can provide covered, enclosed containers for staff meals. Facilities staff said they would follow up with cafeteria personnel and Aramark/Aeramax to resolve the serving and equipment issues.

Facilities staff emphasized reuse and cost control — moving existing trailers, reassigning space and sequencing trades — as strategies to reduce capital costs and keep projects on schedule.